China DIN System Fittings

China DIN System Fittings represent high-quality hydraulic connectors engineered to meet the rigorous specifications defined by the German Institute for Standardization (DIN). Manufactured in China, these fittings combine advanced production techniques with strict quality control processes to ensure precision, durability, and leak-free performance in even the most demanding high-pressure environments.

Leveraging state-of-the-art forging and CNC machining, China DIN System Fittings are designed with metric threads and a 24°cone seat—features that are crucial for delivering reliable and consistent connections in modern hydraulic systems. With an emphasis on both cost efficiency and technical excellence, these fittings are widely used across various industries, including industrial machinery, automotive, and energy sectors, ensuring that every fluid transfer system operates safely and efficiently.

By integrating international standards with localized manufacturing expertise, China DIN System Fittings offer a competitive edge in both performance and affordability. This robust product range not only meets global quality requirements but also provides versatile solutions tailored to the evolving needs of hydraulic applications.

DIN 2353 Hydraulic Tube Fittings Union

24°cone fitting types with Metric thread

German,French,Japanese, Russia and China standards

DIN 2353 Hydraulic Tube Fittings Union

24°cone fitting types with Metric thread

German,French,Japanese, Russia and China standards

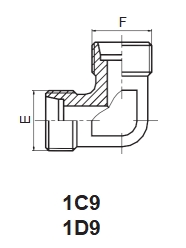

DIN 2353 Hydraulic Tube Fittings Union ELBOW

Most Popular DIN Metric Hydraulic Fittings In Europe And China.

DIN 2353 Hydraulic Tube Fittings Union ELBOW

Most Popular DIN Metric Hydraulic Fittings In Europe And China.

Hydraulic Hose Fittings DIN

There are two kinds of connections: Hose fittings with ISO 8434-1 and ISO 8434-4 24 deg cone end with o-ring. It is a connection to DIN 24 deg cone adapters.

Hydraulic Hose Fittings DIN

There are two kinds of connections: Hose fittings with ISO 8434-1 and ISO 8434-4 24 deg cone end with o-ring. It is a connection to DIN 24 deg cone adapters.

DIN 2353 90° ELBOW FITTINGS

90° Elbow Fittings (DIN 2353 / ISO 8434-1) Definition:

A 90° Elbow Fitting is a type of hydraulic fitting designed to connect two pipes or tubes at a 90° angle. This fitting is used to change the direction of fluid flow in a hydraulic system while maintaining a smooth, efficient flow path. The connection is made using metric threads (ISO 261) and a 24° compression (bite-type) sleeve connection, ensuring a secure, leak-free seal.

DIN 2353 90° ELBOW FITTINGS

90° Elbow Fittings (DIN 2353 / ISO 8434-1) Definition:

A 90° Elbow Fitting is a type of hydraulic fitting designed to connect two pipes or tubes at a 90° angle. This fitting is used to change the direction of fluid flow in a hydraulic system while maintaining a smooth, efficient flow path. The connection is made using metric threads (ISO 261) and a 24° compression (bite-type) sleeve connection, ensuring a secure, leak-free seal.

Trustworthy China DIN System Fittings Manufacturer

At Jiayuan Hydraulics, we pride ourselves on being a trusted China DIN System Fittings Manufacturer committed to delivering precision-engineered, high-quality products that meet international standards. Our state-of-the-art production facilities and rigorous quality control protocols ensure that every fitting we produce adheres to the strict specifications required by the Deutsches Institut für Normung (DIN).

With years of expertise in the hydraulic industry, we leverage advanced manufacturing techniques such as CNC machining and specialized forging processes to produce fittings with exact metric threads and the industry-standard 24°cone seat design. This guarantees leak-free connections and outstanding performance in high-pressure environments, making our products highly reliable in various applications—from industrial machinery and automotive systems to energy and construction sectors.

We understand the importance of both quality and cost efficiency. That is why, at Jiayuan Hydraulics, we continuously invest in innovative technology and skilled craftsmanship to offer our customers competitive pricing without compromising on quality. Every product undergoes extensive testing and meets rigorous certifications, ensuring that our fittings not only deliver exceptional performance but also provide long-lasting durability under even the most demanding conditions.

As a pioneer in the hydraulic fittings industry, we have built a reputation for reliability, consistency, and technical excellence. We strive to exceed our customers’expectations by offering customized solutions tailored to their specific needs while maintaining a commitment to safety, efficiency, and environmental sustainability.

We are Jiayuan Hydraulics—and as a trustworthy China DIN Hydraulic Fittings Manufacturer, our mission is to provide you with the confidence and quality you need for your hydraulic systems to perform at their best.

Advantages of China DIN System Fittings

China DIN System Fittings offer numerous advantages that make them a competitive and reliable solution for modern hydraulic systems. These benefits stem from the combination of rigorous adherence to international standards, advanced manufacturing processes, and the cost-effective production capabilities available in China. Here are some of the key advantages:

| Industry | Application | Key Benefits | Example Equipment |

| Industrial Machinery | Hydraulic control units, power systems | Reliable, leak-free performance under high pressure;efficient assembly | CNC machines, injection molding presses |

| Construction | Hydraulic cylinders, actuators | Durable connections;high pressure tolerance;vibration resistance | Excavators, bulldozers, cranes |

| Agriculture | Hydraulic steering, implement controls | Consistent fluid power;ease of maintenance;robust sealing | Tractors, harvesters, combines |

| Aerospace &Defense | Actuation systems, landing gear | High reliability;precise pressure control;standardization for critical systems | Aircraft hydraulic systems, defense equipment |

| Marine | Steering systems, winches | Excellent corrosion resistance;secure fittings in harsh environments | Ships, offshore rigs, marine winches |

1. Precision and Standardization

China DIN System Fittings are manufactured in accordance with the strict specifications set by the Deutsches Institut für Normung (DIN). This ensures that every fitting features accurate metric threading and the industry-standard 24°cone seat design. The precision and consistency in dimensions allow for seamless integration into hydraulic systems worldwide, providing leak-proof and reliable connections.

2. Superior Durability and Robust Construction

Utilizing advanced forging techniques and state-of-the-art CNC machining, these fittings are built for strength and resilience. They are crafted from high-quality materials such as carbon steel, stainless steel, and brass—each selected based on the application’s demands. This robust construction enables the fittings to withstand high-pressure conditions and harsh operating environments, extending their service life and reducing maintenance requirements.

3. Exceptional Leak Resistance

The carefully engineered designs of China DIN System Fittings, particularly features like the precision-machined tapered threads and cutting-ring or O-ring sealing systems, ensure a tight and secure connection. This results in outstanding leak resistance, which is critical for maintaining system pressure and operational efficiency in hydraulic circuits.

4. Cost-Effectiveness and Competitive Pricing

One of the standout advantages is the production efficiency enabled by China’s advanced manufacturing infrastructure. High production volumes coupled with streamlined supply chains help reduce costs, making these fittings competitively priced without compromising on quality. This cost-effectiveness makes them an attractive option for industries seeking to optimize their budgets while ensuring top-notch performance.

5. Versatility and Customization Options

China’s hydraulic fittings manufacturers offer a wide range of DIN fittings that cater to various industrial applications—from industrial machinery and automotive systems to energy generation and construction equipment. In addition to standard products, manufacturers are able to provide customized solutions tailored to specific system requirements. This flexibility ensures that customers can find or design a fitting that perfectly matches their technical specifications and operational needs.

6. Global Compliance and Quality Assurance

Many Chinese manufacturers hold certifications such as ISO 9001 and comply with DIN and other international standards, ensuring that their products meet global quality requirements. This level of compliance means that these fittings can be confidently used in projects worldwide, contributing to improved safety and consistent performance in hydraulic systems.

7. Rapid Production and Reliable Supply

Due to modern manufacturing practices and efficient logistics, China DIN hydraulic fittings are produced at scale, ensuring quick turnaround times and reliable supply. This is especially beneficial for large-scale industrial projects or when replacement parts are needed on short notice.

FAQs

Q1:What are the main advantages of using China DIN System Fittings?

A1:China DIN System Fittings are engineered to meet strict international standards. They offer precise metric thread designs, robust construction, and excellent leak resistance—ensuring reliable performance in high-pressure environments. They are also cost-effective due to advanced manufacturing processes, making them ideal for industries such as industrial machinery, automotive, and construction.

Q2:How do DIN hydraulic fittings differ from JIC hydraulic fittings?

A2:DIN hydraulic fittings typically feature metric threads and a 24°cone seat designed according to the Deutsches Institut für Normung standards. In contrast, JIC fittings use a 37°flare design, which is popular in North America. Although both types ensure secure, leak-proof connections, the choice between DIN and JIC depends on the system design and regional standards.

Q3:What quality control measures do you use at Jiayuan Hydraulics?

A3:At Jiayuan Hydraulics, quality is our top priority. We employ state-of-the-art CNC machining and forging processes along with rigorous inspection protocols to ensure that every product meets international standards. Our fittings undergo extensive testing for pressure, durability, and leak resistance before leaving our production facility.

Q4:Can these hydraulic fittings be customized?

A4:Yes, we offer customization services. Customers can request tailored solutions to match specific design requirements or operational conditions. Our engineering team works closely with clients to modify dimensions, materials, and finish options while maintaining compliance with relevant standards.

Articles Selected for You

How to Choose the Right DIN Hydraulic Fitting for Your System

What You Need to Know the Application of Hydraulic Fittings

DIN hydraulic fittings manufacturer recommendation

Top 10 Hydraulic Fitting Manufacturers 2025

Top 10 Hydraulic Fitting Manufacturers in China 2025